Need to treat your biogas ?

|

|

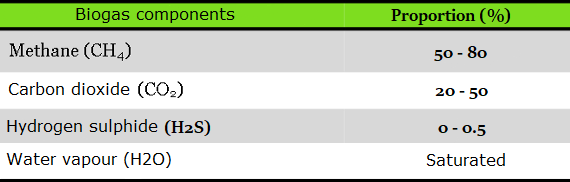

- Properties of biogas

Biogas contains mainly methane and dioxide carbon. Other gases can be present in small quantities

like hydrogen, hydrogen sulphide and water vapour. The biogas composition is closely dependent on the nature

of the fermented waste and the degree of progress in the fermentation process.

The biogas is intended to be burned in a boiler, or in a cogeneration unit. An excessive level

of water vapour and hydrogen sulphide tends to corrode materials in particular valves of boilers and engines.

- Our solution

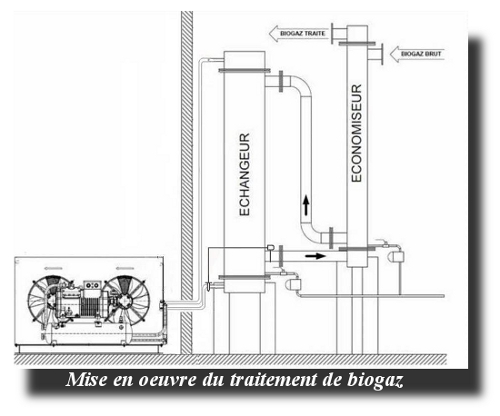

To avoid this problem, Kempro Environnement proposes to treat the biogas by cooling to 5°C in heat exchanger related to a refrigeration unit. The aim is to eliminate a significant portion of water by condensation and to inject water to solubilized the hydrogen sulphide. An additional treatment by activated carbon can be used to eliminate residual hydrogen sulphide.

- Operating principle

The principle is to cool the biogas from 30°C to 5°C with the aid of refrigeration unit, to condensate water. The hydrogen sulphide being soluble in water, it is eliminated in large part with the condensate. Given that the biogas is intended to undergo a combustion, it is not necessary to hold the low biogas temperature. The cold biogas can be used to pre-cool the hot biogas and thus reduce the power of refrigeration unit. An exchanger raw biogas-clean biogas allows to cool the biogas to be treated with the biogas treated.

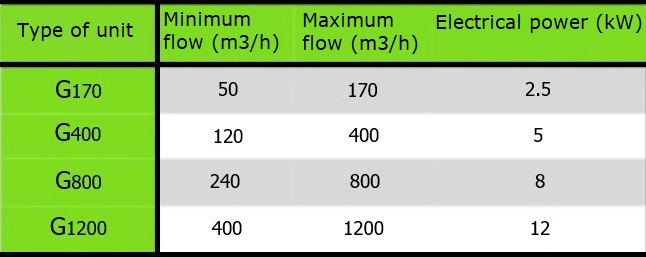

- Technical characteristics