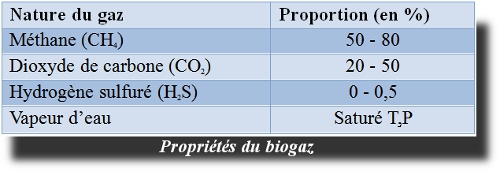

Properties of the biogas Biogas consists mainly of methane and carbon dioxide. Other gases can be added to a minor extent in the composition of biogas hydrogen, hydrogen sulfide (H2S), water vapor. The composition of biogas depends strongly on the nature of the waste methane and the degree of progress of the digestion.

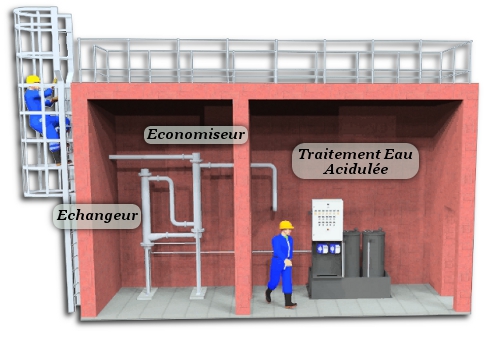

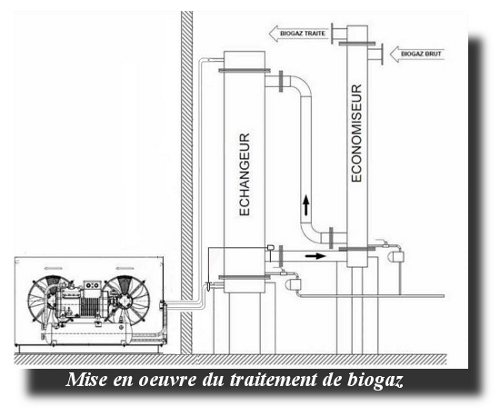

Our solution To avoid this, Kempro Environment proposes to treat the biogas by cooling to 5 ° C in a heat exchanger connected to a chiller and inject water at the same time. Principle of operation The treatment principle adopted is to cool the biogas of 30 ° C to 5 ° C with a chiller to condense much of the water vapor in it and inject it into the condenser water. Hydrogen sulphide is soluble in water, it is removed to a large extent with the condensate. Since biogas is for combustion, it is not necessary to maintain low temperature, we can with biogas cold, pre-cool the hot gas and thus reduce the power of the chiller. Exchanger biogas / biogas called "saver" allows to cool the biogas process with biogas Treaty.

effectiveness The effectiveness of treatment of biogas to cold gives several advantages:

Implementation The biogas passes through the economizer from top to bottom on the shell side. The condensed water is collected at the foot saver. Biogas treated side tube passes through the exchanger from the bottom up.

|